| Place of Origin: | China |

| Brand Name: | ECOGRACE |

| Certification: | SGS, ISO |

| Model Number: | GED200 |

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 10000-50000 USD / set |

| Packaging Details: | container |

| Delivery Time: | 1 months since order confirmed |

| Payment Terms: | T/T ,L/C |

| Supply Ability: | 200sets/ month |

| APPLICATION: | Aluminium Melting Furnace , Leads Melting Furnace , Copper Furnace | MATERIAL: | Stainless Steel |

|---|---|---|---|

| WORKING TEMPERATURE: | 150 Degree | FILTER AREA: | 300 M2 |

| FILTER SPEED: | 0.8-1.2m/min | SERVICE LIFE: | 2 Months |

| SIZE OF FILTER BAG: | 120*3600mm | QTY OF FILTER BAGS: | 100 Degree |

| PACKING: | In Woven Bags |

Ecograce Pulse jet dust collection system is the most efficient and cost effective types of dust collectors. Baghouse dust collectors as a mature dedusting equipment has been widely used in various industries.

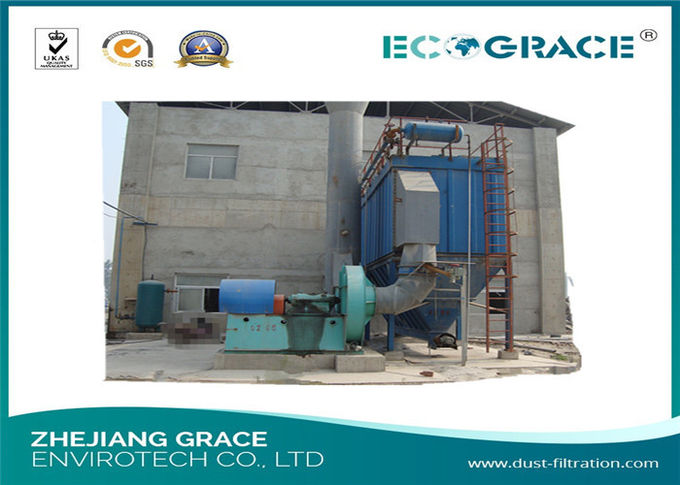

The Pictures of Dust Collector

Working Principle of Baghouse Pulse Jet Dust Collector

1. The dust-laden air enters the bag filter.

2. The dust / powder separates inside the bag filter chamber.

3. The air is uniformly distributed avoiding channelling while the powder is separated.

4. Initially a layer of material dust forms on the filter bags acting as a filtration layer.

5. The dust is accumulated on filter elements while the air passes through the filter bags from outside to inside.

6. The accumulated powder is dislodged from the filter bags by reverse pulsejet air intermittently.

7. The cake released powder falls on bottom cone and is discharged through powder discharge valves.

8. The dust free air is sucked by induced draft fan ID Fan and is exhausted to atmosphere.

Advantage:

1, compartment side spray, loop timing purge.

2, bag working temperature 240 ° C, instant 260 ° C.

3, the filtration efficiency more than 99%;

4, the emission concentration ≤ 30 mg/Nm3, air leaking percentage ≤ Level 1

| Spec./ Pef.parameter | GED-20 | GED-32 | GED-45 | |

| Filter area m2 | 20 | 32 | 45 | |

| Airflow m3/h | 1800-2400 | 2880-3840 | 4050-5400 | |

| velocity of filtering m/min | 1.5-2 | 1.5-2 | 1.5-2 | |

| resistance Pa | 980 | 980 | 980 | |

| efficiency % | 99 | 99 | 99 | |

| Using temperature°C | <150 | <150 | <150 | |

| The wind machine |

model | 4-72-11 | 4-72-11 | 4-72-11 |

| Air Volume m3/h | (1975-3640) | (2430-5408) | (4020-7420) | |

| wind pressure Pa | 1245-784 | 1617-1068 | 1999-1313 | |

| Motor Model | Y90-L-2 | Y100L-2 | Y132S1-2 | |

| Electric motor capacity KW | 2.2 | 3 | 5.5 | |

| Vibrating machine |

amplitude mm | 4 | 4 | 4 |

| motor type | Y90S-4 | Y90S-4 | Y90S-4 | |

| Electric motor capacity KW | 1.1 | 1.1 | 1.1 | |

| Vibrating machine | size | YJD-6200×200 | YJD-6200×200 | YJD-6200×200 |

| Electric motor capacity KW | 0.6 | 0.6 | 0.6 | |

What is the details of our dust collector ?

1. GRACE BAG FILTER DUST COLLECTOR, it has taken the temperature gas to lower temperature gas inlet structure, the rough high temperature granules directly drop to the dust hopper and effectively protects the filter bag.

2. The longer filters dust collector take smaller area which will increase the processing capacity, therefore it is more convenient for reconstruction of old factories.

3. GRACE take separate chamber off line dust cleaning in bag filter dust collector design and it is with high efficiency and few secondary flour dust attachment, meanwhile it can effectively save the energy consumption. Such design effectively protect the filter bags and pulse valve and save the operation and maintenance cost for the dust collector system.

4. The filter bags will be replaced without stop the filtration system.

5. GRACE Dust Collector with GRACE made filters which is made with snap band with good sealing, easy for assemble and replacement and good tightness.

6. GRACE take Air leaking detecting with oil and to keep all the system air leaking <0.5%.

7. Our Bag Filter Dust Collector is controlled by PLC to realize automatic dust cleaning, dust removal, automatic temperature control and over temperature alarm.

Contact Person: Miss. Doreen Zou

Tel: 0086 135 8806 5995

Fax: 86-571-86073956