| Place of Origin: | China |

| Brand Name: | ECOGRACE |

| Certification: | SGS, ISO |

| Model Number: | 160X4500mm |

| Minimum Order Quantity: | 300PCS |

|---|---|

| Price: | 10~30USD/PCS |

| Packaging Details: | container |

| Delivery Time: | 7-45 days |

| Payment Terms: | T/T ,L/C |

| Supply Ability: | 50000pcs/month |

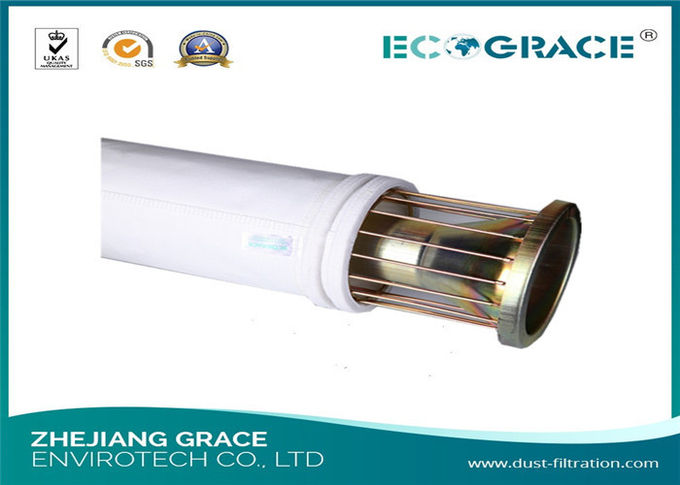

| PRODUCT: | Stainless Steel Filter Cage 160X4500mm | MATERIAL: | Stainless Steel |

|---|---|---|---|

| SPECIFICATION: | 160X4500mm | FILTER AREA: | 5 M2 |

| WORKING TEMPERATURE: | Around 200 Degree | PACKING: | In Woven Bags |

| THICKNESS: | 2.5mm | WEIGHT: | 1 KG |

ECOGRACE supply the full range of filter bag cage , galvanized surface treatment , organic silicon treatment for carbon steel filter cage , and stainless steel filter cages.

Filter bag cage is the rib of the filter bag and it should be convenient to install and maintain. The quality of filter bag cage will directly decide the working efficiency and service life of the filter bag. Galvanized steel filter bag cage, which is warmly welcomed for its hardness, light weight and smooth. For the surface treatment, we can provide spray coating, silicon coating and galvanized, all of them can improve their hardness and make them away from corrosion. And filter cage with venturi can provide better protection for the filter bag.

The Filter cage is a rib of a filter bag and it should be light and easy for installation and maintenance. The quality of a cage has directly bearing on the filtering state and service life of a filter bag. Every cage we make can meet the requirement for tightness, smoothness and uprightness.

1.material of the filter cage: Carbon Steel / SS 304 SS 316 SS316L

2.type of cage: any type

3.type of the horizontal bar: Any type

4.surface treatment:Galvanized or silicon powder plated .

The vertical bar, horizontal ring, spacing ring, length, the diameter of the ring and the shape of the cage can be according with the requirement from client.

The thichkness of the longitudinal wire can be Φ3, 3.2, 3.5, 3.8, 4.

Characteristics of SS/ Mild Steel Filter Cage

1, Strong heat resistance.

2, Better protection for the filter bag and connection with the dust collector.

3, High dust collection efficiency.

4, No corrosion, long service life.

What can we provide for you?

1, Professional and patient reply for the consulations.

2, High qualified products.

3, Competitive price against other suppliers.

4, Professional instruction during the installation.

5, Continuous and stable after-sale service.

Technical Specification:

| Series: | PPS550gsm |

| Material: | PPS (RYTON) 450 – 650g/sq.m needle felt |

| Fibre: | 100% PPS / RYTON staple fibre (Toray / Toyobo, Japan original fibre, or Chinese fibre available) |

| Scrim: | 100% PPS / RYTON staple fibre (Toray / Toyobo, Japan original fibre, or Chinese fibre available) |

| Weight: | 400 – 650g/m2 (customized) |

| Finishing: | Heat setting, single side singeing, calendering (double sides finishing would be available upon request) |

| Specifications: | Customized according to drawing / sample |

| Packaging: | Polybag in cartons |

| Applications: | Coal-fired power plant, waste incinteration plant, circulating fluidized bed boilers, etc. |

| Delivery Time: | 7-45 days |

| Payment Terms: |

Contact Person: Miss. Doreen Zou

Tel: 0086 135 8806 5995

Fax: 86-571-86073956